PRODUCTS

TWIN SCREW EXTRUDER COMPOUNDING LINE

Providing high-quality, uniform compounding and customized solutions based on specialized technology, precision control, and optimal screw combinations.

CORE EQUIPMENT

- TWIN SCREW EXTRUDER

- CONTINUOUS DOUBLE SCREEN CHANGER

- CUTTING SYSTEM

- COOLING VIBRATOR SCREEN

- AUXILIARY EQUIPMENT :

WATER BATH, AIR WIPER, FEEDER, COOLING UNIT ETC

PURPOSE

1. Material Mixing and Dispersion

Uniformly mixing and dispersing raw materials to produce high-quality compounds.

2. Material Property Improvement

Enhancing physical and chemical properties to provide optimal results tailored to customer needs.

3. Productivity Improvement

Maximizing production volume and reducing time and costs through high-speed and high-efficiency processes.

4. Optimal Solution Provision

Modular design enables equipment configuration to meet application fields and customer demands.

5. Process Automation and Control System

Enhancing process automation levels and enabling real-time monitoring and management through control systems.

FEATURE

1. Twin Screw Design

Two screws rotate co-directionally to maximize kneading performance, providing uniform dispersion and mixing.

2. Modular Configuration

Customizable solutions for various materials and process requirements by combining screw elements and barrels.

3. Precision Process Control

Maintaining process consistency and quality by controlling temperature, pressure, speed, etc., in real-time.

4. Multi-Process Stages

Capable of handling various processes such as mixing, dispersion, reaction, and devolatilization in a single line.

5. High-Efficiency Production

Maximizing energy efficiency while maintaining high productivity to reduce costs.

6. Flexible Applicability

Applicable to a wide range of industries by processing various materials such as plastics, rubber, and chemicals.

7. Low Energy Consumption

Providing eco-friendly operating conditions by maximizing energy efficiency.

APPLICATION

CHEMICAL

POLYMER

RECYCLING

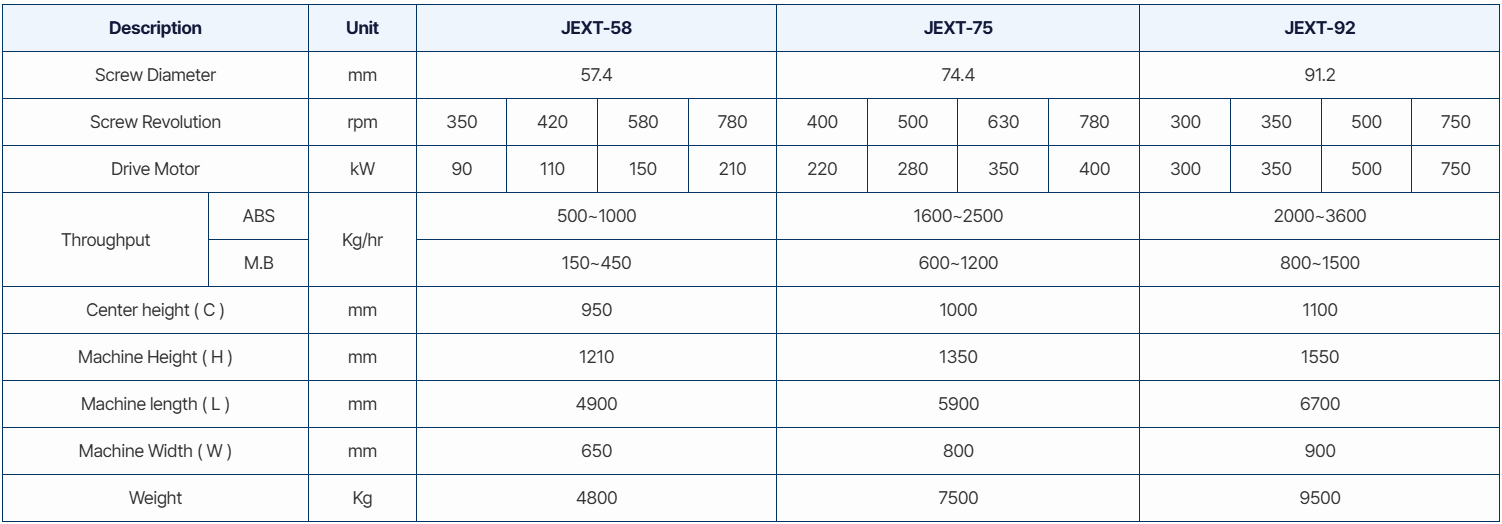

TECHNICAL DATA SHEET

| Description | Unit | JEXT-58 | JEXT-75 | JEXT-92 | ||||||||||

| Screw Diameter | mm | 57.4 | 74.4 | 91.2 | ||||||||||

| Screw Revolution | rpm | 350 | 420 | 580 | 780 | 400 | 500 | 630 | 780 | 300 | 350 | 500 | 750 | |

| Drive Motor | kW | 90 | 110 | 150 | 210 | 220 | 280 | 350 | 400 | 300 | 350 | 500 | 750 | |

| Throughput | ABS | Kg/hr | 500~1000 | 1600~2500 | 2000~3600 | |||||||||

| M.B | 150~450 | 600~1200 | 800~1500 | |||||||||||

| Center height ( C ) | mm | 950 | 1000 | 1100 | ||||||||||

| Machine Height ( H ) | mm | 1210 | 1350 | 1550 | ||||||||||

| Machine length ( L ) | mm | 4900 | 5900 | 6700 | ||||||||||

| Machine Width ( W ) | mm | 650 | 800 | 900 | ||||||||||

| Weight | Kg | 4800 | 7500 | 9500 | ||||||||||