PRODUCTS

F.R LINE

Delivering optimized kneading & dispersion solutions for masterbatch production through the combination of high-performance twin-screw extruders and pressurized kneaders.

CORE EQUIPMENT

- DISPERSION KNEADER

- TWIN CONICAL FEEDER

- CUTTING SYSTEM

- PELLET DRYER

PURPOSE

Ensuring optimal quality in the masterbatch manufacturing process by concentrating various additives and pigments at high concentrations and dispersing them uniformly.

FEATURE

Fusion of Twin-Screw Extruder and High-Performance Pressurized Kneader.

Enabling rapid disassembly and assembly through the adoption of hydraulic clamps at the raw material feed section.

Uniform Mixing and High Dispersion Efficiency.

APPLICATION

MASTER BATCH

CHEMICAL

POLYMER

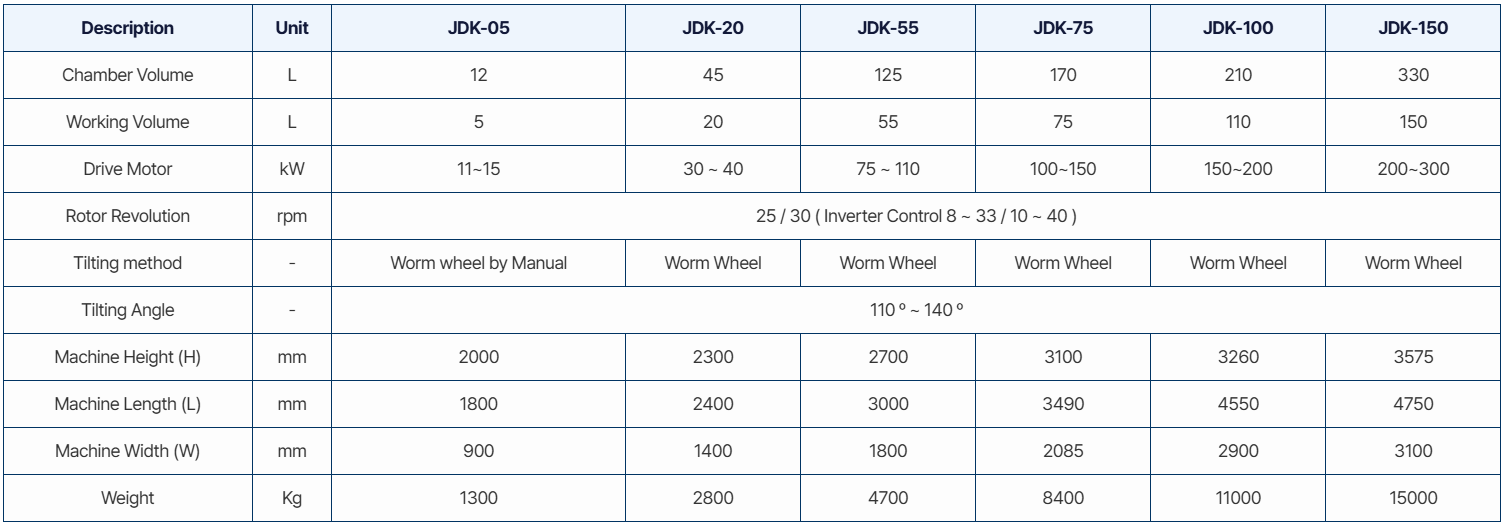

TECHNICAL DATA SHEET

| Description | Unit | JDK-05 | JDK-20 | JDK-55 | JDK-75 | JDK-100 | JDK-150 |

| Chamber Volume | L | 12 | 45 | 125 | 170 | 210 | 330 |

| Working Volume | L | 5 | 20 | 55 | 75 | 110 | 150 |

| Drive Motor | kW | 11~15 | 30 ~ 40 | 75 ~ 110 | 100~150 | 150~200 | 200~300 |

| Rotor Revolution | rpm | 25 / 30 ( Inverter Control 8 ~ 33 / 10 ~ 40 ) | |||||

| Tilting method | - | Worm wheel by Manual | Worm Wheel | Worm Wheel | Worm Wheel | Worm Wheel | Worm Wheel |

| Tilting Angle | - | 110 º ~ 140 º | |||||

| Machine Height (H) | mm | 2000 | 2300 | 2700 | 3100 | 3260 | 3575 |

| Machine Length (L) | mm | 1800 | 2400 | 3000 | 3490 | 4550 | 4750 |

| Machine Width (W) | mm | 900 | 1400 | 1800 | 2085 | 2900 | 3100 |

| Weight | Kg | 1300 | 2800 | 4700 | 8400 | 11000 | 15000 |