PRODUCTS

MIXING SYSTEM

Ensuring stability and uniformity by homogeneously mixing various materials.

Various impeller and jacket designs are applied for effective dispersion and mixing of materials, greatly enhancing production process efficiency and mixture quality.

- SUPER MIXER & COMBI MIXER & LAB MIXER

- COOLING MIXER (BLENDER)

- ADDITIVE MIXER

- FLOATING MIXER

- COLORING MIXER

- HIGH SPEED MIXER

SUPER MIXER & COMBI MIXER & LAB MIXER

Used as key equipment in compounding processes due to high-speed mixing and high homogeneity, providing efficient mixing performance under various material and process conditions.

Excellent blending efficiency with rotating upper/lower impellers and deflectors.

PURPOSE

1. High-Speed Mixing

Forming uniform mixtures by rapidly mixing polymers, additives, fillers, etc., at high speed in a short time.

2. Ensuring Homogeneity

Improving product quality and realizing material properties (strength, durability, etc.) through uniform dispersion of materials.

3. Process Efficiency

Saving production time and energy with rapid mixing, ensuring efficiency in mass production.

FEATURE

1. Safe and Uniform Mixing

Maintaining product consistency through rapid and uniform mixing via high-speed rotation and even dispersion of additives.

2. Application of Various Impellers

Customizable mixing tailored to material characteristics.

3. Fully Enclosed Structure

Maintaining a clean process by preventing dust scattering and foreign substance intrusion.

4. Scalability of Application Range

Applicable to various materials such as secondary batteries, polymers, and additives.

APPLICATION

CHEMICAL

POLYMER

RECYCLING

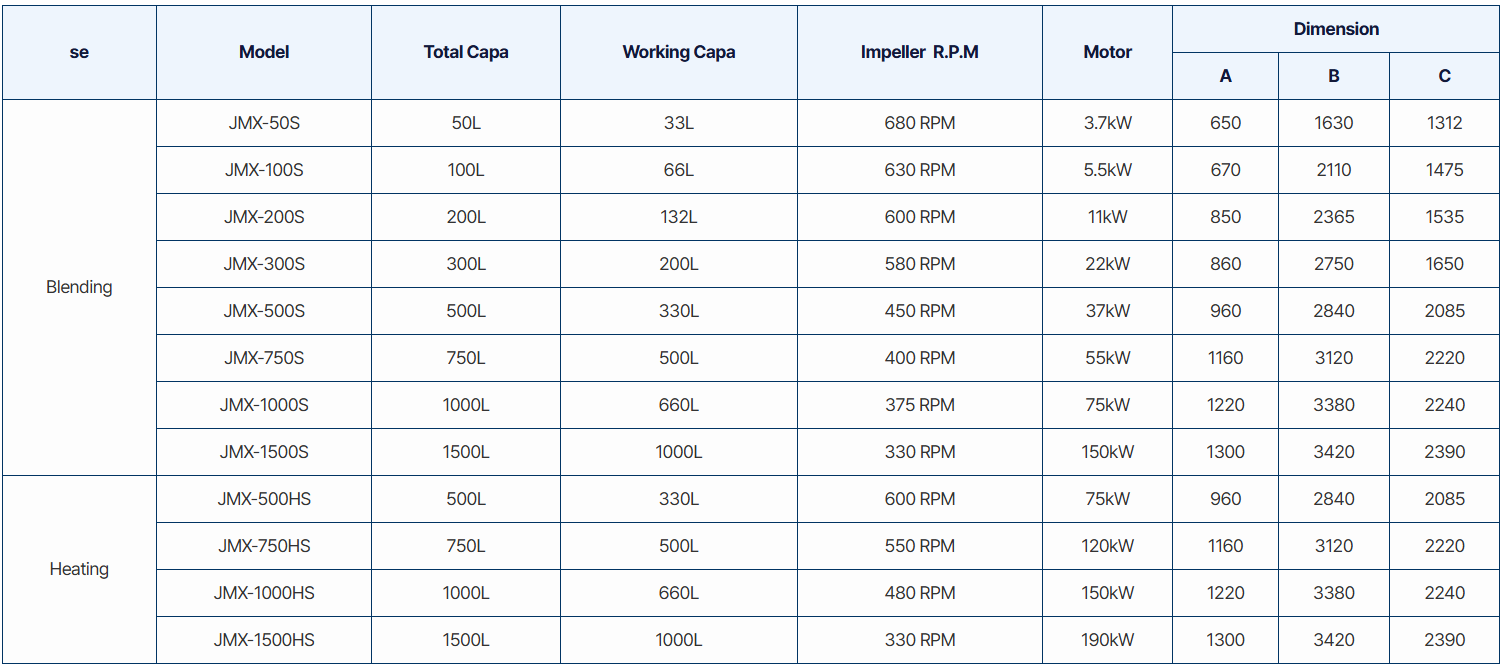

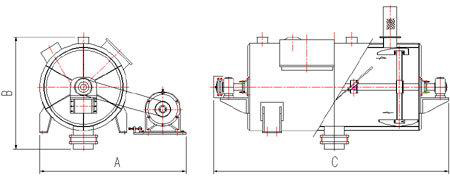

TECHNICAL DATA SHEET

| se | Model | Total Capa | Working Capa | Impeller R.P.M | Motor | Dimension | ||

| A | B | C | ||||||

| Blending | JMX-50S | 50L | 33L | 680 RPM | 3.7kW | 650 | 1630 | 1312 |

| JMX-100S | 100L | 66L | 630 RPM | 5.5kW | 670 | 2110 | 1475 | |

| JMX-200S | 200L | 132L | 600 RPM | 11kW | 850 | 2365 | 1535 | |

| JMX-300S | 300L | 200L | 580 RPM | 22kW | 860 | 2750 | 1650 | |

| JMX-500S | 500L | 330L | 450 RPM | 37kW | 960 | 2840 | 2085 | |

| JMX-750S | 750L | 500L | 400 RPM | 55kW | 1160 | 3120 | 2220 | |

| JMX-1000S | 1000L | 660L | 375 RPM | 75kW | 1220 | 3380 | 2240 | |

| JMX-1500S | 1500L | 1000L | 330 RPM | 150kW | 1300 | 3420 | 2390 | |

| Heating | JMX-500HS | 500L | 330L | 600 RPM | 75kW | 960 | 2840 | 2085 |

| JMX-750HS | 750L | 500L | 550 RPM | 120kW | 1160 | 3120 | 2220 | |

| JMX-1000HS | 1000L | 660L | 480 RPM | 150kW | 1220 | 3380 | 2240 | |

| JMX-1500HS | 1500L | 1000L | 330 RPM | 190kW | 1300 | 3420 | 2390 | |

※ Please contact us for LAB MIXER technical specifications.

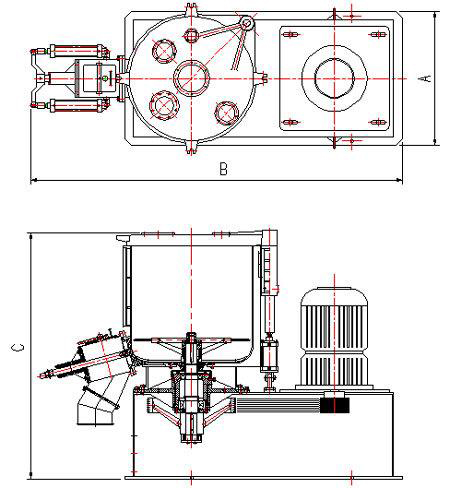

DIMENSION

COOLING MIXER (BLENDER)

Maintaining the quality and characteristics of PVC products through rapid cooling after high-temperature mixing.

Maximizing productivity with a design that enhances cooling efficiency and maintenance convenience.

PURPOSE

1. Cooling and Stabilization

Maintaining product quality and characteristics through rapid cooling of high-temperature mixtures.

2. Product Quality Improvement

Preventing thermal deformation and providing uniform temperature distribution.

FEATURE

1. Spiral Cooling Jacket

Implementing fast and efficient cooling through a wide heat exchange surface area.

2. Easy-to-Replace Impeller

Reducing maintenance costs and time with easy replacement in case of wear.

3. Durability and Stability

Ensuring reliability with the use of high-durability materials.

4. Uniform Cooling

Contributing to defect-free product manufacturing by ensuring thermal stability.

APPLICATION

CHEMICAL

POLYMER

RECYCLING

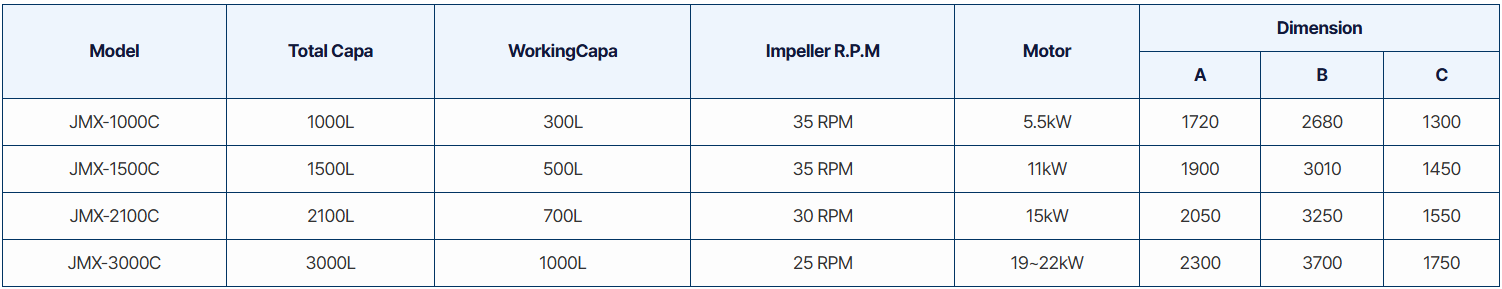

TECHNICAL DATA SHEET

| Model | Total Capa | WorkingCapa | Impeller R.P.M | Motor | Dimension | ||

| A | B | C | |||||

| JMX-1000C | 1000L | 300L | 35 RPM | 5.5kW | 1720 | 2680 | 1300 |

| JMX-1500C | 1500L | 500L | 35 RPM | 11kW | 1900 | 3010 | 1450 |

| JMX-2100C | 2100L | 700L | 30 RPM | 15kW | 2050 | 3250 | 1550 |

| JMX-3000C | 3000L | 1000L | 25 RPM | 19~22kW | 2300 | 3700 | 1750 |

DIMENSION

ADDITIVE MIXER

Producing high-quality products through high-efficiency mixing and uniform dispersion of additives.

Playing an important role in various industries with excellent cooling efficiency and maintenance convenience.

PURPOSE

1. Uniform Additive Mixing

Realizing desired material properties (strength, durability, color, etc.).

2. Maximizing Mixing Efficiency

Achieving uniform dispersion with a combination of impeller and deflector.

3. Cooling and Quality Maintenance

Maintaining product quality through heat dissipation via a jacket.

FEATURE

1. Dual Impeller System

Achieving fine grinding and dispersion simultaneously with raw material mixing.

2. Ease of Cleaning

Easy-to-clean internal structure prevents contamination and facilitates maintenance.

3. Expanding Additive Application Range

Enabling uniform dispersion of various additives.

APPLICATION

CHEMICAL

POLYMER

RECYCLING

FLOATING MIXER

Equipment optimized for small-batch material compounding, enhancing work efficiency and ease of cleaning.

Improving blending efficiency and enabling mixing of various additives through high-speed vibration function.

PURPOSE

1. Small-Quantity Additive Compounding

Maintaining quality through uniform mixing of precise materials.

2. Maximizing Work Efficiency

Providing simplified input/output processes and an easy-to-clean structure.

FEATURE

1. Suitable for Small-Quantity Colorant Compounding

Optimized for high-precision color realization and use of special additives.

2. Pneumatic Lifting and Lowering

Easy internal cleaning and maintenance after mixing.

3. Vinyl Bag Input and Discharge

Preventing foreign substance contamination and supporting quick work transitions.

4. Impeller Rotation and High-Speed Vibration

Reducing material loss and improving mixture homogeneity.

APPLICATION

CHEMICAL

POLYMER

RECYCLING

COLORING MIXER

Uniformly mixing colorants into raw materials to maintain color consistency and quality.

Playing an important role through high productivity and mixing efficiency.

PURPOSE

1. Efficient Compounding of Small-Quantity Colorants

Aiming for Precise Color Realization

2. Worker Safety Protection

Preventing musculoskeletal disorders and increasing convenience.

3. Maximizing Cleaning and Work Efficiency

No cleaning required during color changes.

FEATURE

1. Suitable for Small-Quantity Colorant Mixing

Enabling fast and accurate compounding of various colors.

2. Easy Input Method

Enabling transition without production stoppage during color changes using a vinyl bag input method.

3. Drum Rotation and Swing Motion

Ensuring mixing efficiency and uniform color quality.

4. Worker Protection Design

Ensuring safety and convenience with an ergonomic design.

APPLICATION

CHEMICAL

POLYMER

RECYCLING

HIGH SPEED MIXER

Supporting product quality improvement and process efficiency through electrode slurry mixing in secondary battery processes.

PURPOSE

1. Electrode Slurry Mixing

Uniform mixing for optimizing electrical performance.

2. Efficient Production Process

Improving production speed and saving energy through rapid mixing.

3. Consistent Product Quality

Improving battery performance and lifespan by controlling viscosity and homogeneity.

FEATURE

1. High-Speed Mixing

Ensuring slurry homogeneity through powerful rotational force.

2. Optimized Design

Application of special materials to prevent metallic foreign substance contamination.

3. Fully Enclosed Structure

Minimizing dust and maintaining a clean working environment.

4. Temperature and Viscosity Control

Managing heat generated during mixing and maintaining consistent viscosity.

5. Automation and Ease of Operation

Simplified condition setting and monitoring through a control system.

APPLICATION

SECONDARY BATTERY

RECYCLING